- Posts: 312

- Thank you received: 4

Beginner: Welding

9 years 9 months ago #146662

by trucksyd

Beginner: Welding was created by trucksyd

gday, i recently bought a welder as my inter has a bit of rust here & there. i got myself a ross mig welder which has gasless & gas functions, i have never used one but thought it would be a cheaper alternative than paying someone as i am doing up a couple of other vehicles...

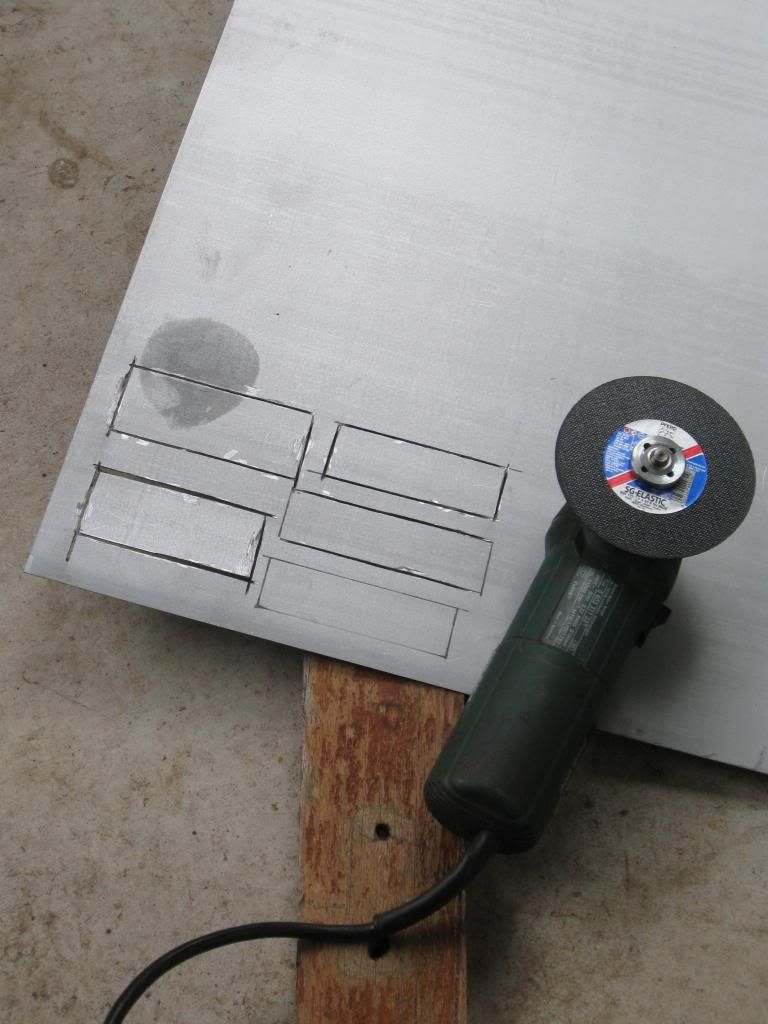

i asked around as to the best panel steel to use & ZINC ANNEALED 0.9MM APPARENTLY IS THE GO. I paid $45 for a 2m sheet...

that little grinding disc was available at the steel shop for $3 , they slice through the steel easily & last a while.

i have been practising on the steel just cutting & welding they are all obviously pretty rough , but i have been doing it on my days off for the last month. just trying to get the settings correct . i set it up to start with a slow wire feed . & have set it to about number 3 .& have the gas turned down to its lowest setting ,the mob whom i bought the gear from are at 99,batt st ,penrith

the photo here withg the pencil & paper is a bit blurred but is a good way to mark out your steel.i am not sure how the panel beaters do it but i got a pencil a dark one ( or darker & some thick tracing paper from the newsagent , i cut the steel section first on the truck & then slowly traced ,then i marked onto the steel sheet. after that i carefully cut with grinder.

or darker & some thick tracing paper from the newsagent , i cut the steel section first on the truck & then slowly traced ,then i marked onto the steel sheet. after that i carefully cut with grinder.

after gently shaping the steel piece , it fits quite accurate ,so i spot a few welds in.

after grinding down the patches i bogged over it , then sanded with 36 grit. this leaves quite deep gouges so i went over it again with 320 grit to smooth it all out . there were some little spots that needed going over again so i got the bog out & wiped a little over these spots. ... this post is just to help you blokes that have been thinking about getting your truck pass through rego etc.... . i am sure there are pro welders on this forum that can pick mistakes with my welding ,i am hoping the rust doesnt show through ! but hopefully it can help a few .....

i asked around as to the best panel steel to use & ZINC ANNEALED 0.9MM APPARENTLY IS THE GO. I paid $45 for a 2m sheet...

that little grinding disc was available at the steel shop for $3 , they slice through the steel easily & last a while.

i have been practising on the steel just cutting & welding they are all obviously pretty rough , but i have been doing it on my days off for the last month. just trying to get the settings correct . i set it up to start with a slow wire feed . & have set it to about number 3 .& have the gas turned down to its lowest setting ,the mob whom i bought the gear from are at 99,batt st ,penrith

the photo here withg the pencil & paper is a bit blurred but is a good way to mark out your steel.i am not sure how the panel beaters do it but i got a pencil a dark one (

after gently shaping the steel piece , it fits quite accurate ,so i spot a few welds in.

after grinding down the patches i bogged over it , then sanded with 36 grit. this leaves quite deep gouges so i went over it again with 320 grit to smooth it all out . there were some little spots that needed going over again so i got the bog out & wiped a little over these spots. ... this post is just to help you blokes that have been thinking about getting your truck pass through rego etc.... . i am sure there are pro welders on this forum that can pick mistakes with my welding ,i am hoping the rust doesnt show through ! but hopefully it can help a few .....

Please Log in to join the conversation.

9 years 9 months ago #146663

by indianman

Replied by indianman on topic Re: Beginner: Welding

G'day good onya for having a go mate nothing like sitting back looking at the finished job knowing you did it yourself  . I see you have a gas bottle but which wire are you using? I have always had trouble getting a nice weld with gasless wire always seem very dirty, much nicer with the gas and plain wire.

. I see you have a gas bottle but which wire are you using? I have always had trouble getting a nice weld with gasless wire always seem very dirty, much nicer with the gas and plain wire.

Jon

Jon

Please Log in to join the conversation.

9 years 9 months ago #146664

by trucksyd

Replied by trucksyd on topic Re: Beginner: Welding

Thanks mate, I have been using gas wire (copper look) 0.6 ... But I find when I use a tiny bit of gas it works good, I tried it without any gas & it seems ok ,but as I said before I am just getting the hang of it ,& the welds are still lumpy ,

Please Log in to join the conversation.

9 years 9 months ago #146665

by Zuffen

Replied by Zuffen on topic Re: Beginner: Welding

Before you cut up any more steel put the guard back on your grinder.

Best way to get a piece of steel in your eye is no guard.

I wear good Bolle safety glasses and I had steel in my eye after it burn the inside of the glasses lens. And yes I had the guard on the grinder (never remove it) but Sod's Law prevails. My Optometrist says I shouldn't be able to see out of my eyes due to lens grinding to get rid of the rust.

I notice many American TV shows have guys working without the guard so that makes it acceptable for others to follow. >

Best way to get a piece of steel in your eye is no guard.

I wear good Bolle safety glasses and I had steel in my eye after it burn the inside of the glasses lens. And yes I had the guard on the grinder (never remove it) but Sod's Law prevails. My Optometrist says I shouldn't be able to see out of my eyes due to lens grinding to get rid of the rust.

I notice many American TV shows have guys working without the guard so that makes it acceptable for others to follow. >

Please Log in to join the conversation.

9 years 9 months ago #146666

by scratcha

1418 Benz now really impressing the bride

Replied by scratcha on topic Re: Beginner: Welding

just be sure you have the polarity correct with that welder, the leads need to be swapped - to + when you change from gasless to gas. if the weld "boils" you need more gas.

Ill find a link if i can to help.

Scratcha

Ill find a link if i can to help.

Scratcha

1418 Benz now really impressing the bride

Please Log in to join the conversation.

9 years 9 months ago #146667

by trucksyd

Replied by trucksyd on topic Re: Beginner: Welding

When I first got it it was set up for gasless , it came with a roll of gasless wire, but then I went & got the gas bottle , & swapped the -&+..also changed to 5kg gas wire.. But when I weld it

seems to run a bit better without the gas...

seems to run a bit better without the gas...

Please Log in to join the conversation.

9 years 9 months ago #146668

by mammoth

Replied by mammoth on topic Re: Beginner: Welding

I am not qualified as a welder but a few clues. it's the gas that provides the electric plasma for mig welding to work, so with too little you will get rough and spotty welds. About 12 to 15 on the flow gauge. Higher wire speed affects the current, so when changing one for a different job you change the other as well. When there is a gap between the pieces being welded go from one side to the other, back and forth, in a semi circle and imagine you are pulling a string of goo as you go. The edges lead and the middle follows, always maintaining a molten pool. Adjust your mask darkness so you can see properly.

Cutting like that without a guard, it won't just be sparks in your eyes to worry about but your whole face if a disc breaks apart.

For people with a few $$$ plasma cutters are now the way to go.

Keep at it and it will come good.

Cutting like that without a guard, it won't just be sparks in your eyes to worry about but your whole face if a disc breaks apart.

For people with a few $$$ plasma cutters are now the way to go.

Keep at it and it will come good.

Please Log in to join the conversation.

9 years 9 months ago #146669

by swamprat

D1510 International 4wd 6BT cummins power steer

Replied by swamprat on topic Re: Beginner: Welding

try setting your gas on about 12lpm if you are working inside out of the wind or up to about 20 lpm if there is any breeze too much gas wont hurt the weld it will just mean you waste gas if using to much , too little gas & you will get porosity in the weld which will look like honeycomb & have no strenght in it,make sure you are using gas wire not the wire with the "flux" inside it , you will need very little gap between the steel patch & panel you are welding when working with sheet metal , by varying your wire speed you should be able to change the weld from a flat weld to one that stands quiet high , if you have the gap very small between the two peices of steel you can turn up the power a little bit which will make welding easier ,& remember that the steel needs to be clean , sometimes you need to grind off the coating to get a good weld , hope this is of some help , im certainly no expert but have welded a fair bit over the years , welding is 10% theory 90% practice ,

D1510 International 4wd 6BT cummins power steer

Please Log in to join the conversation.

9 years 9 months ago - 9 years 9 months ago #146670

by jon_d

Replied by jon_d on topic Re: Beginner: Welding

And hold the grinder with 2 hands.

It only takes a fraction of a second to catch and then run up your pants grinding and slicing all the way up to your ...... well you know what I mean.

I too, had a bit of grinding stone or steel get under the googles and stick to the eye. Very lucky, but it was there long enough to rust onto the eyeball.

With the hole, here's a tip.

Cut 2 pieces, one is about 5 mm bigger than the hole. One is 2 mm smaller than the hole.

Center them and spot them together. Screw a self tapper into the middle, leaving most of the thread and head out.

Thread it into the hole and then pull it up tight against the inside wall. (The big piece is acting like a back block when plastering). Then simply spot the gap in a few places and then run a bead. It doesn't buckle, and you get a waterproof weld. Grind the top off and smear with bog.

Oh and another tip for the unwary; don't attach the earth to the anything that has a bearing. Otherwise, you can weld/pit the bearing as the current flows through it.

It only takes a fraction of a second to catch and then run up your pants grinding and slicing all the way up to your ...... well you know what I mean.

I too, had a bit of grinding stone or steel get under the googles and stick to the eye. Very lucky, but it was there long enough to rust onto the eyeball.

With the hole, here's a tip.

Cut 2 pieces, one is about 5 mm bigger than the hole. One is 2 mm smaller than the hole.

Center them and spot them together. Screw a self tapper into the middle, leaving most of the thread and head out.

Thread it into the hole and then pull it up tight against the inside wall. (The big piece is acting like a back block when plastering). Then simply spot the gap in a few places and then run a bead. It doesn't buckle, and you get a waterproof weld. Grind the top off and smear with bog.

Oh and another tip for the unwary; don't attach the earth to the anything that has a bearing. Otherwise, you can weld/pit the bearing as the current flows through it.

Last edit: 9 years 9 months ago by jon_d.

Please Log in to join the conversation.

9 years 9 months ago #146671

by dodgy35

Replied by dodgy35 on topic Re: Beginner: Welding

Fully support the "Be carefull with the guardless grinder" theory.Those thin slitting discs can leave a nasty cut.Have personally lost a bit of bark in the past on more than just the one occasion lol.With the welding side of things I found good value with some of the tutorial type vids on Youtube.When making up patch panels I tend to sometimes resort to making up cardboard templates,it works for me  .

.

PS.Nice to see another Pinball person messing with old trucks as well.

PS.Nice to see another Pinball person messing with old trucks as well.

Please Log in to join the conversation.

Time to create page: 0.559 seconds