- Posts: 748

- Thank you received: 49

6v53 reassemble

- wedgetail84

-

Topic Author

- Offline

Long story short - I'm cleaning/reassembling and possibly rebuilding some bits of this 6v53 twin turbo to put in my C1800 inter (not as a work truck of course, more a fun but fully rego'd run about/ute). It was shut down at idle with powder 10 years ago 300hrs after a rebuild then pulled down. I'm starting off where the PO left it.

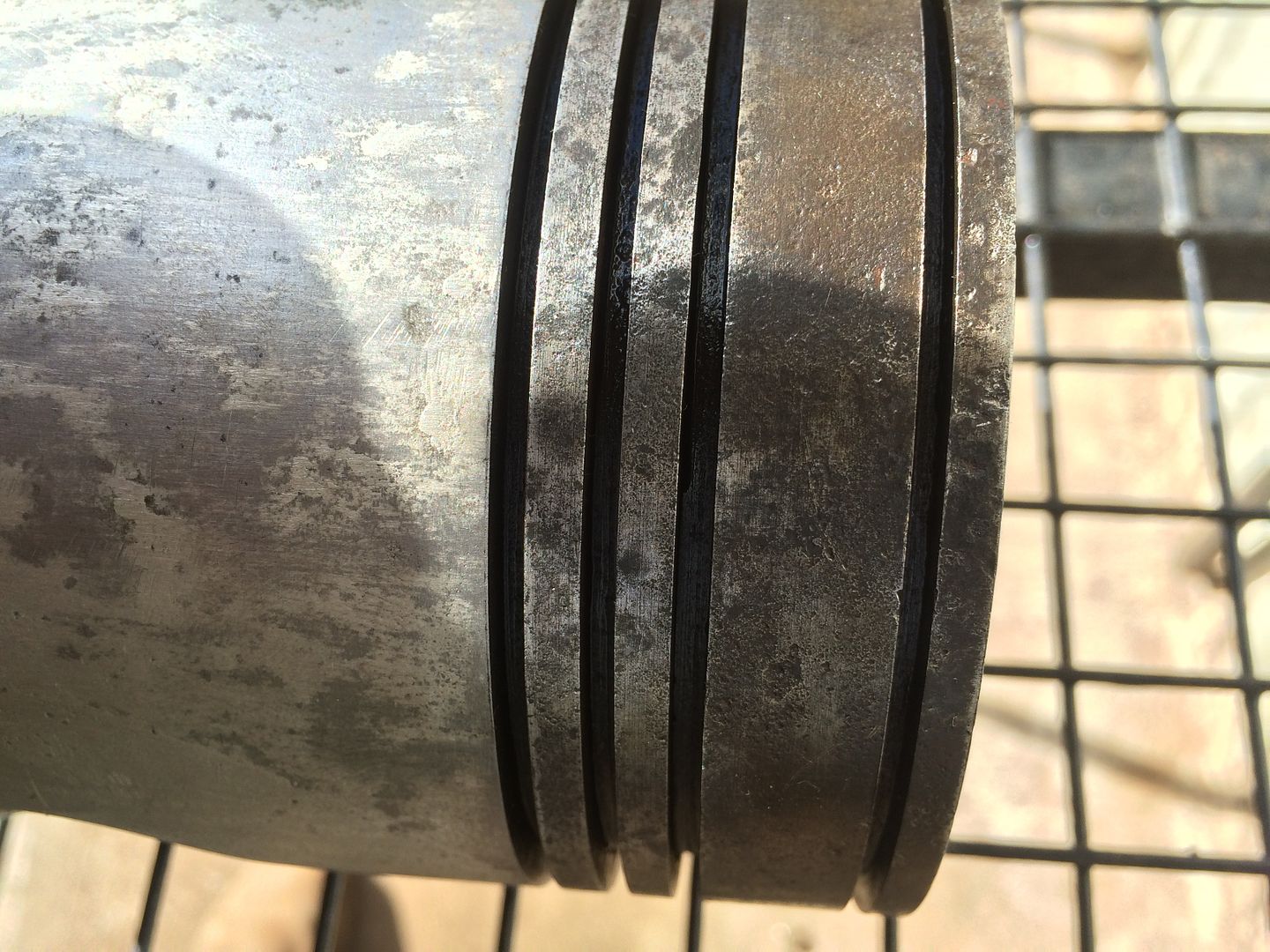

Starting on the pistons, I removed one from a liner (they're all stuck) after heating it and using a press. The rings were very stuck, wouldn't move at all being hit with a punch or straight with a hammer. Rather than patiently waiting for the right chemicals I got stuck in with an oxy and heated the piston a bit. Ground a screw driver into a plugging-chisel shape I was able to dig the ends of each one out (frequently regrinding the screw driver). Took a few goes but eventually got them all out. The compression rings were surprisingly malleable, and I didn't break any. Is this because I heated (annealed) them? The bottom oil rings shattered when I hit them with a centre punch.

Removed the pin retainer caps by pushing a small screw driver through and prizing out. The pin is 1 3/8, and is quite stained. No damage (marks are my oily finger prints) but can feel some (but not all) of the staining. Bushes look good IMO, can feel a very slight amount of play. Book says max of 0.01 for used parts, it feels less than this but I think I need to bight the bullet and get a set of micrometers for this project. Can anyone recommend something good but affordable? Would go for second hand...

Hit the piston with some W&D and scraped the grooves out. Who would run this and who wouldn't? Need to find my hone then will do the liner and check for clearance. The book says find a feeler gauge that fill fit and pull out with 6# of force so will do that. So far it they're all like this I'm seriously considering using them unless everyone thinks I'm off the wall?

pockmarked piston before cleaning

Liner after wire brusing

piston bushing/retainer surface

rod bearing

rod bushing

piston pin

oil grooves

compression grooves

after cleaning the piston up with W&D

Please Log in to join the conversation.

If the gudgeon pins show more than, say 3/4 of the original surface then I reckon they're fine. Think of the micro pitting as micro oil reservoirs

Providing all the clearances and bores come out OK, I'd say you're good to go with rings, gaskets, seals and those gudgeon plug thingies (learning stuff all the time).

Cheers, Jarrod.

“I offer my opponents a bargain: if they will stop telling lies about us, I will stop telling the truth about them”

― Adlai E. Stevenson II

Please Log in to join the conversation.

- Posts: 837

- Thank you received: 0

Please Log in to join the conversation.

Nutter

Gudday M8

SORRY

But gotta disagree wiff U

@ Wedgy Gr8 expense n time we B all learn n sum

n all boils down to how much he value$ his time

it will run

Screemers have bin known to get up n purr4m wen bits R broken n miss n

NothingVentured ....... NothingGained

LOL

cya

OF ALL THE THINGS EYE MISS ................. EYE MISS MY MIND THE MOST

There's more WORTH in KENWORTH

Please Log in to join the conversation.

- wedgetail84

-

Topic Author

- Offline

- Posts: 748

- Thank you received: 49

well I see your point, but unfortunately it isn't relevant to me right now as I just don't have the money. I'd love to buy a running 6v53 but as a rough one starts at about $2500 which is $2000 too much I'm left with two options - either something like this or none at all. Which would you choose? Maybe nothing and that's fine but I want one and don't mind plugging away at it. I don't have a deadline so can do it the thrifty way where possible. I can afford the odd couple of hundred dollars on a seal kit, ring set or liner seal set every now and again but even if I did manage to save up a couple of grand (which would take a long long time) if I dropped it on an engine for a non-essential truck my family life would be no more and quite rightly so.Just gonna put my 2 Bob in here... That thing is gonna cost you more then twice as much as you think, do a job right the first time if you are going to rebuild it do it once and do it right! I would buy a running motor that is ready to use and drop that one you have in the scrap bin. I'm not trying to offend you and sorry if I have but sometimes it's better to cut your losses and move on better to do it now then go through the pain of it again later

As swishy pointed out, it won't be time wasted even if it comes to nothing. Besides I don't believe it will and I have the drive to finish it even if it takes a while

Please Log in to join the conversation.

Please Log in to join the conversation.

Mr Nut and I have an opinion in common, but that's not the point as you have just pointed put in your latest post.

I too had a similar experience to you with an old 504 Peugeot diesel. (see? I can still even spell it right >

Mongrel beggar of a thing and curses on and on and so forth until the air is blue and you get tired of reading euphemisms for curse words.

It started out as love and I couldn't be turned.

Then it became a challenge that I wouldn't let go of.

I kept it going for about 6 month longer than was good for me, but I did keep it going.

It all turned to shite in the end but that's not the point either.

I learnt a lot about the French method of manufacture

Knowledge doesn't weigh much and it doesn't take up any extra space in your brain and its yours for ever

(if you can remember "wut it wuz euh lerd in thu firs plase").

Anyway, all is good now and I don't have to take medication anymore.

Go for the 6v53 reassemble.

Your going to learn plenty of stuff you never knew you needed to know before.

Even if it is as simple as me and my Pug.

"I'll never go near another French bloody car ever again in my whole life even if I live to be 100 years old and its the last car on the planet with wheels"

Bugger it, sometimes it really is the journey that counts and not the destination.

Enjoy your project and I'll watch quietly from over here.

cya

-b

Mucking about on the edge

Please Log in to join the conversation.

Just keep in mind that these engines was built with pre WW2 technology and more often than not, rebuilt in much the same way your doing, but usually on the side of a road or in a paddock somewhere. And besides that, its not like you'll be running it at full noise 12 hours a day, 7 days a week.

And even if the whole project turns to poo at the end, you will have gained valuable experience and that is something money cannot buy...

Please Log in to join the conversation.

Your photos are great, good detail, show all the warts. I hope you post a few "after" pics when you're ready to put her together.

When you get this engine purring, this thread is going to be a real help to the next guy who tackles a junk 53 series. And you are going to be an expert on 53 series Detroit SJDs.

I'll try to clarify the acid question. The stuff I'm talking about is a compound of acids and detergent meant for cleaning aluminum, mainly on trailers, and goes on in a solution (20 water, 1 cleaner to start, stronger if it's a stubborn job). You start from the bottom (use a brush), do a section at a time (keep it wet) and rinse with cold water. It does a great job of cleaning oxide, smoke and road dirt. I've used a lot of it over the years, observed precautions and still have all my flesh and (too much) fat. I first used it straight for parts recon when I took a scrap air compressor off the pile and refurbished it for my shop. The passages inside the heads were filled with bloom rust and the RTV that the last fool had used instead of the proper head gaskets was smeared all over everything. I laid them in a heavy plastic parts tub and covered them with the cleaner straight. The next morning they looked like they did when they came from the factory save a bit of pitting on the block mating surfaces. I shaved them gently to a smooth surface and assembled the unit. That was 25 years ago and it's still making air every day. I have since used the compound to clean thermostat housings, water pumps, cast iron, steel, aluminum bits, you name it. The stuff works when nothing else will. Use your common sense, observe the necessary precautions, and you'll be fine. I just checked with Fleetpride (truck and trailer supply outfit, nationwide in US) and they're still selling it, so it can't be too bad or the nanny state would have banned it. Made by WAB, USD25.00/gallon, less if you buy the five gallon jug, I'd be surprised if it or something like it isn't available in Australia. I think the concerns expressed in the preceding thread are all about straight hydroflouric acid, which this definitely isn't.

All the advice you get on a forum like this is free, and a cynic might say that's it's worth what you pay for it. But I've seen some real good points on here, and I'm sure you can sort it out. We're all pullin' for ya.

Regards,

Mark

Please Log in to join the conversation.

Many years ago a mate of mine put a 903 back together for a mob that didn't want to spend any money and I gave him a hand with it. We did it in a yard that they had been dumping concrete washout in, dust everywhere. We went through all the second hand 903 liners we had lying around, used the ones with minimal electrolysis, gave them a hone, used a second hand ring set out of a motor that had done bugger all, in fact, I think the only parts that were bought was gaskets. That motor ran beautifully, and I used to see that truck working around Brisbane for 5 years or more after that working for QRX and old mate didn't have any trouble.

As you know, you've got very little to loose and a lot to gain.

Please Log in to join the conversation.